Line-of-Sight Blockchain-Based Predictive Analytics

Interoperable Supply Chain Enterprise NFTs for Access Control and Financing

Disruptions to the global supply chain are increasingly common these days. We all see the empty shelves at the market. Employees are working shorter shifts and feeling the crunch of lost wages. And, it’s costing businesses billions of dollars with no end in sight.

No other industry affects as many people simultaneously as the supply chain. From the roof over our heads and the food on our plates to the clothes on our backs and the phones in our pockets, everything is impacted by today’s fractured supply chain.

Take car manufacturing as just one example. Recent events from a cold snap in Texas resulting in electricity shortages to droughts in Taiwan and the fallout from COVID have drastically slowed chip production. The consequences have had a rippling effect from suppliers to consumers and the slowdown is expected to last into next year. Assuming chip production does ramp up, port congestion is the next hurdle that awaits.

Both the sudden halt and subsequent ramp-up in consumer purchasing have wreaked havoc on the supply chain. Varying degrees of COVID restrictions, a breakdown in off-terminal logistics (diminished rail capacity and longer truck turnaround times), shipping container shortages coupled with the increased demand have led to warehouses at capacity and bogged down ports. The result is delays, shortages, and increased pricing at retailers.

General Motors Lays off Employees

After weeks of forced on and off scheduling for employees, General Motors recently announced they had to temporarily lay off 5,000 workers at its Flint Assembly plant in Michigan. Disruptions in suppliers’ semiconductor chip production coupled with port congestion have led to a shortage of parts. GM has also halted production at two other plants.

Although GM says the move is temporary, the damage has been done. This type of layoff will have a cascading effect on the suppliers, truckers, and others resulting in increased costs and lost revenue for GM as well as anyone associated with GM. Those losses will cycle back to the suppliers, vendors, and ultimately the consumer with increased pricing.

Tesla Not Immune

General Motors isn’t the only one feeling the burden of a struggling supply chain. This year Tesla was forced to, briefly, halt production on its Model 3. Elon Musk recently told investors that Tesla has experienced significant supply chain hurdles citing the global chip shortage, port delays, and COVID-19 restrictions in China.

These are just two examples of disruptions to the supply chain from chip shortages, there are more. Further issues have been reported in beef production and other retail goods. Dragonchain can’t account for the weather or geopolitical landscape however we have tools and solutions for businesses to remain flexible, predict possible outcomes, and react when problems present themselves.

Predictive Analytics for Supply Chain Optimization

Through the use of predictive analytics, a business can remain flexible and mitigate costs from slowed productivity. Predictive analytics is the process where businesses look at current and historical data patterns to determine if those patterns are likely to emerge again.

Predictive analytics employs a series of techniques including artificial intelligence (AI), data mining, machine learning, modeling, and statistics to find patterns that identify risks and opportunities.

A business can use these techniques to fine-tune its supply chain by adjusting resources in response to possible future events, improve operational efficiencies, and reduce risks associated with events outside of its control.

It is not enough to know that 1597 cogs are in container number 2584. A business with insight into the events that led up to those cogs being loaded into the container will be able to react quickly to subtle changes before they become bigger issues. The ability to know what has happened in the past and what is happening now can help businesses predict what may happen in the future.

Blockchain-Based Predictive Analytics

Dragonchain believes once data is on-chain what you can do with that data is limitless. Businesses naturally collect immense amounts of information from the supply chain. Blockchain can be used to provide better data integrity and better evidence of past data. When using on-chain data in predictive analytics models it becomes much easier to analyze any definable data set. Coupled with a marketplace to incentivize the behaviors of partners, businesses can improve analytics and more accurately predict outcomes.

Past, Present, and Future

Supply chain predictive analysis involves analyzing events along the supply chain that occurred in the past, are occurring now, and predicting what might happen in the future.

With on-chain data, a business can conduct a post mortem examination of past events to identify times when there was a breakdown along the supply chain. They can see what happened at the source such as broken equipment or a staffing shortage. Businesses can also see what was happening in the environment during that time such as a weather event or other geopolitical event. That information is then combined with real-time data of what is currently happening along the supply chain. Those data sets can be analyzed to produce a statistical report of possible outcomes and make adjustments to its supply chain to mitigate the negative repercussions of an event.

For example, let’s say a business typically receives a specific part from another country 4000 miles away. With real-time blockchain-based reporting, the business sees that production has slowed. They can then examine what is happening in the supplier’s environment such as bad weather or some other geopolitical event. The business can then see what happened the last time something similar occurred and change suppliers to protect their supply chain before there is a problem.

This ability on a global scale would have drastically reduced the disruptions to the supply chain during COVID. At the first signs of problems in China, manufacturers could have sought new suppliers from other locations.

It doesn’t need to be a pandemic. Even the smallest disruption can affect every person along the supply chain. In just 2-3 days one event on the other side of the world will have a ripple effect that could cost a business billions of dollars. Yet, these types of situations are common even without natural disasters or unexpected pandemics.

Prediction-Based Marketplace and Process Improvements

Predictive analysis can be used for process improvements and to ensure more accurate self-reporting from supply chain partners to better predict future outcomes.

To motivate supply chain partners to accurately report data, a business can build a prediction-based marketplace. Data from current and past events along the supply chain can be added to the marketplace and used by partners to predict the outcome of a future event for a reward. The more accurate the prediction the larger the reward. Therefore, partners are incentivized to provide better reporting so they can more accurately predict outcomes themselves.

A marketplace can also be used for process improvements. As an example, a partner can add a contract with a delivery deadline into the marketplace. If the delivery is early they get a 5% bonus. If the delivery is on time, there is a 1% bonus. But if the delivery is late then there is a penalty of 5%. This can incentivize the behavior of partners to meet delivery deadlines and keep production running.

Additionally, a business will be able to identify inefficiencies with the incentivization of accurate reporting. For instance, a report could show the entire supply chain process went smoothly except with one particular vendor. The business could use the report to prove the state of the supply chain with that particular vendor and change to a different vendor.

One of the biggest barriers to accurate reporting and planning is the lack of interoperability between different partners. Without it, businesses don't have the tools or ability to analyze data points to plan for future disruptions. Many in the supply chain industry are trying to solve the interoperability challenge but success is limited.

Flawed Interoperability Networks

A new solution referred to as a supply chain collaboration network (SCCN) is a network of trading partners. The network includes a “many-to-many” architecture where a community of data partners and third-party data feeds provide supply chain visibility and analytics across the supply chain.

The network groups existing network solutions including industry-specific networks, transportation management, and other forms of collaborative supply chain applications which previously could not communicate with each other. With SCCNs businesses can identify supply chain risks in near real-time.

The use of an SCCN seems like a great way to connect these siloed networks, however, there is a major flaw in the design -- supply chain security and privacy. The networks within the SCCN are all open to each other. This means they are all exposed even if only one business in the network has a data breach. The rippling effect can span across the globe from supplier to business to customer. Establishing industry networks should be met with specific criteria to ensure data privacy and security.

How do we ensure a business can see the entire supply chain system and remain protected from security and data breaches along the way?

Line-of-Sight Supply Chain Management Solutions

Currently, businesses lack an adequate line-of-sight into all aspects of their supply chain. Off-the-shelf software applications are siloed, not interoperable, and fail to deliver solutions to the problems businesses face. A better solution is an interoperable blockchain where sensitive data remains private yet proof of all operations is decentralized.

Supply Chain Interoperability with Proof

The Dragonchain architecture uniquely provides for the segregation of data so that all private and proprietary information remains under the control of the business. Businesses can connect their existing systems to their own private blockchain quickly through the use of RESTful APIs. This means that a business can integrate IoT devices, RFIDs, or any other systems into its business blockchain to ledger data points and share selected information with select partners without exposing sensitive data.

Once a business records data on its private blockchain ledger, the proof of that data is sent for decentralized verification. Once verified the proof is secured to multiple public blockchains (e.g. Bitcoin and Ethereum) with billions of dollars of measurable security.

What does that all mean?

It means that when a supplier sends a part to the container ship, the port authority receives proof of that event but they are not privy to the purchasing order (perhaps with the billing information) of the cog used to make the product. The port authority is given only the information needed and nothing else. They do not need to know how the product was produced. They only need their specific information to accept the shipment. Supply chain Enterprise NFTs (ENFTs) can be used to control this type of access to information. (See below for more on supply chain ENFTs)

Current software solutions generally only indicate what is in each container at the port. These solutions are broadly limited in their applications to the shipping container level. However, a supply chain management solution needs to go beyond just the shipping container at the port. Being able to interop systems quickly, segregate data points, and deploy to any environment can completely streamline the entire supply chain.

By using Internet of Things (IoT) devices and Artificial Intelligence and Machine (AI/ML) Learning, the supplier’s system can provide an immutable record of every event even before a product is loaded on a container ship. This gives businesses valuable insight into the entire supply chain.

For example, a supplier across the globe may tell a company that they’ve sent a particular car part for delivery but in reality, the supplier wasn’t being honest and the car part is still sitting idle in the warehouse. By the time the company realizes that the car part is not coming in on time as expected, it's too late, and the company has lost six or eight weeks of production time.

The completely interoperable supply chain management solution can provide advanced line-of-sight into the actual state of the supplies. Businesses will be able to see problems before they even get to the port and the ability to make adjustments to protect the supply chain.

Security

A secure line-of-sight interoperable supply chain management solution is possible with Dragonchain due to its architecture. Segregated data ensures the people along the supply chain have access to only the information they need and shields each party from exposing sensitive information. Every step along the supply chain is provable with decentralized proof for a secure chain of custody and independent proof of data integrity.

Together with AQED, we offer quantum encryption and signing capabilities at the core of the architecture to protect data at rest and in motion. To minimize downtime due to data breaches, Dragonchain advocates for decentralization and the mirroring of systems so that even if there is a breach, the amount of data exposed is minimized and the businesses are not forced to pay a ransom to access their systems.

Coupled with Dragonchain’s interoperability, businesses have a better line-of-sight into their supply chain and are better able to secure against external threats from partners and suppliers including those from shipping ports or any other stop along your supply chain. The system is better able to protect from non-direct attacks on the business’s partners’ supply chains effectively closing down access points to data.

Enterprise NFT-Based Solutions for Financing, Supply Chain Tracking, and Access Control

Letters of Credit Today

A Letter of Credit (LC) is a promise by a buyer’s bank to pay the seller a specified sum in the agreed currency, provided that the seller submits the required documents by a predetermined deadline. The document outlines and escrows the terms of the deal between two parties and is a multi-step process that can take upwards of 90 days from start to finish.

- The Letter of Credit is issued by the buyer’s bank.

- The Letter of Credit is sent to the seller and the seller’s bank.

- If there is a confirming bank then they guarantee payment even if the issuing bank fails to make it.

- The seller prepares his goods and documents based on the Letters of Credit.

- Once the shipment has been made, the seller gives copies of all documents to his bank.

- The seller’s bank verifies the documents against the specifications from the Letter of Credit. Once satisfied the seller’s bank pays the seller what is due to him as per the price agreed between him and the buyer.

- The seller’s bank then sends all the documents to the buyer’s bank. Once the buyer’s bank verifies the details against the Letter of Credit they reimburse the seller’s bank the money that they paid to the seller.

- The buyer’s bank then informs the buyer they have the documents.

- The buyer then arranges to pay the buyer’s bank the money that has been paid by them to the seller’s bank.

- Upon receipt of these funds, the buyer’s bank then endorses the bill of lading to the buyer so that the cargo can be released to the buyer.

Throughout the entire process used today, it is important to keep in mind that at no time do any of the banks involved verify that the cargo has been loaded on a shipping container or vessel or have proof that the cargo even exists.

Blockchain and Supply Chain Enterprise NFT Solutions for Letters of Credit

A supply chain Enterprise NFT (ENFT) could drastically reduce the intermediaries involved with Letters of Credit and streamline the entire process. A buyer can deposit fiat currency (e.g. USD, EUR) or cryptocurrency into their account within the system. The initial transaction or wire transfer would be provable on-chain. This transaction is then embedded into an ENFT along with the data that tracks where the money came from, the purpose of the money, and the process to which it is committed.

This ENFT token now controls the money and can control access to various parts of the supply chain process. It can move between parties if desired or it can stay with one party until all steps in the process have been verified. When the final delivery occurs, the funds can be withdrawn and the supply chain ENFT can be burned or destroyed.

The ENFT could also be set up to where it will release payment to each person along the supply chain. For instance, the transportation team could be paid as soon as they deliver the product to the port and everything is verified. This gets money in the hands of each person between the buyer and the seller faster.

The benefit of using ENFTs over Letters of Credit is the ability to verify and prove the state at every step of the supply chain process. The system dramatically accelerates port off-boarding and payments. As soon as the cargo arrives at the port the funds can be released.

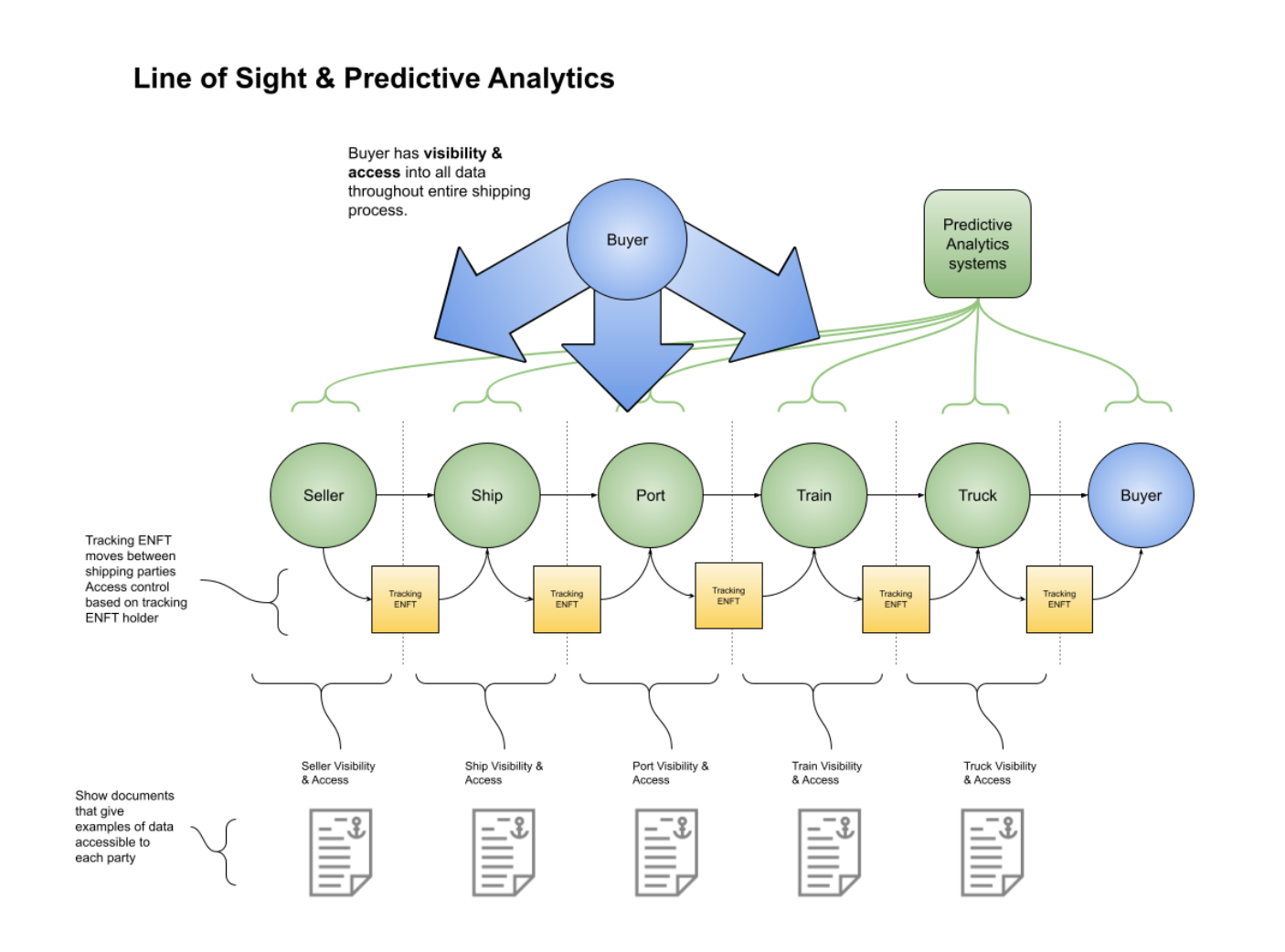

Supply Chain Access Control and Tracking

Beyond controlling money flows, ENFTs can also serve as access control for products and information. A supplier could allow access to information about the shipment such as delivery location and requirements for temperature controls to the transportation team. The access control NFT could then allow the port authority to access the transportation records to prove the product maintained a certain temperature up to delivery. This type of selective communication between different parties along the supply chain extends to the buyer and could even continue to the retail level and the customer.

On-chain data from interoperable IoT devices, RFID tags, or partners allows businesses to track products for real-time reporting on the state of their supply chain. The data can be added to a Tracking ENFT which can move alongside physical items and record every step of the supply chain. These tokens can also serve as a record and proof of the shipment. This information can be used to identify areas where the supply chain may have broken down on a more granular level.

For example, in a situation where a shipment of perishable food went above the stipulated temperature, that data would be on-chain and known to the buyer. The buyer could then see when and where the shipment was when the temperature climbed. If a pattern emerged they could find an alternate way to ship the perishable food. The buyer could even refuse the shipment as it was not in an agreed-upon condition.

Crowded ports, data breaches, and slowed production lines are just a few of the challenges that currently face supply chain management teams. Most things, like the weather, we can’t control. But we can use technology to mitigate the effects severe weather or other obstacles have on a supply chain.

Through the use of interoperable blockchain technology, Dragonchain is uniquely positioned to integrate flexible solutions at scale to give businesses a secure line-of-sight into their entire supply chain to analyze, predict, and adjust quickly to protect against costly downtime.

Contact us today to learn more about how Dragonchain can streamline your supply chain and help you plan for an unforeseen future.